The fashion industry is constantly evolving and adapting to new technologies, consumer demands, and sustainability concerns. Garment manufacturing, in particular, has undergone significant changes in recent years, with the rise of automation, digitalization, and sustainable production methods. In this blog post, we will explore the future of garment manufacturing, highlighting some of the key trends and predictions that are shaping the industry.

1. Automation and Robotics

Automation and robotics are transforming the garment manufacturing industry, making production faster, more efficient, and cost-effective. With the use of computerized cutting machines, sewing robots, and automated ironing and folding machines, the time and labor required to produce a garment have been significantly reduced. Moreover, automation has made it possible to produce high-quality, consistent garments, which can improve the customer experience and reduce waste.

In the future, we can expect to see even more advanced robots and automated systems in garment manufacturing, as well as increased use of artificial intelligence and machine learning to optimize production processes.

2. Digitalization

Digitalization is another major trend that is shaping the future of garment manufacturing. With the use of computer-aided design (CAD) software, designers can create and test virtual prototypes of their designs before manufacturing, reducing the need for physical samples and minimizing waste. Additionally, digital technologies can help optimize production processes, from supply chain management to inventory control.

In the coming years, we can expect to see increased use of digital technologies in garment manufacturing, such as virtual reality and augmented reality tools that allow consumers to try on clothes virtually before purchasing.

3. Sustainability

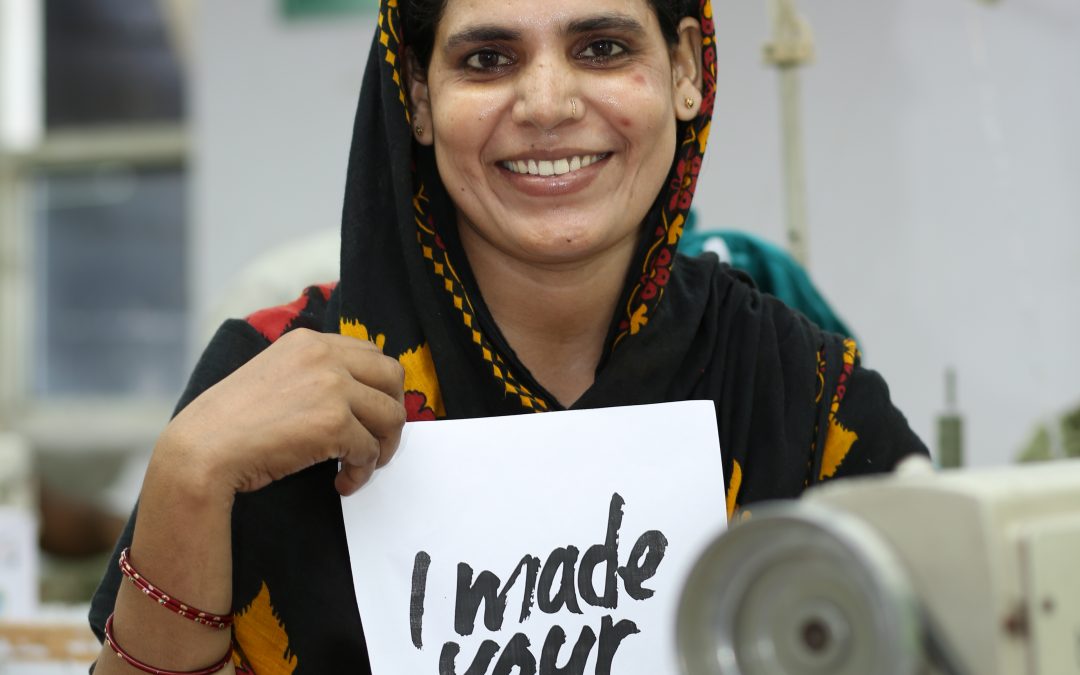

Sustainability has become a top priority for the fashion industry, and garment manufacturing is no exception. With increasing awareness about the environmental and social impact of fast fashion, many brands are adopting more sustainable production methods, such as using organic or recycled materials, reducing water and energy consumption, and implementing circular economy practices.

In the future, we can expect to see even greater emphasis on sustainability in garment manufacturing, as consumers demand more eco-friendly and socially responsible products. This may include the use of innovative materials, such as biodegradable fabrics or plant-based alternatives to synthetic fibers, as well as the adoption of closed-loop production processes that minimize waste and maximize resource efficiency.

4. On-Demand Manufacturing

On-demand manufacturing, also known as made-to-order or bespoke production, is an emerging trend in garment manufacturing that allows brands to produce clothes only when they are ordered by customers, rather than in bulk. This approach can reduce waste and excess inventory, as well as increase the speed of production and delivery.

In the future, we can expect to see more brands adopting on-demand manufacturing, as it offers a more sustainable and customer-centric approach to production. This may also lead to greater customization options for consumers, allowing them to personalize their clothes to their own preferences and body measurements.

5. Collaborative Manufacturing

Collaborative manufacturing is another emerging trend in garment manufacturing that involves multiple stakeholders, such as designers, manufacturers, and suppliers, working together to create products. This approach can help reduce lead times, minimize waste, and increase transparency and traceability throughout the supply chain.

In the future, we can expect to see more collaborative manufacturing initiatives in the garment industry, as brands seek to improve their sustainability credentials and respond to changing consumer demands. This may involve partnerships between brands and suppliers to develop more sustainable materials or production methods, as well as collaborations between designers and manufacturers to create more innovative and eco-friendly products.

Conclusion

The future of garment manufacturing is an exciting and rapidly evolving landscape, with automation, digitalization, sustainability, on-demand manufacturing, and collaborative production all shaping the industry’s direction. As consumer demands continue to evolve, brands will need to adapt to stay competitive, adopting new technologies and production methods that prioritize sustainability, efficiency, and buyer experience.

Recent Comments